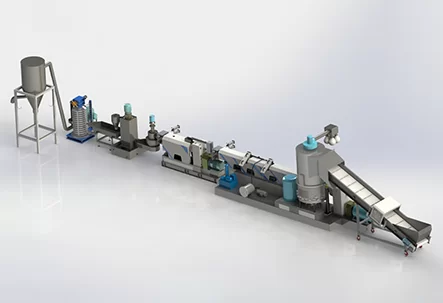

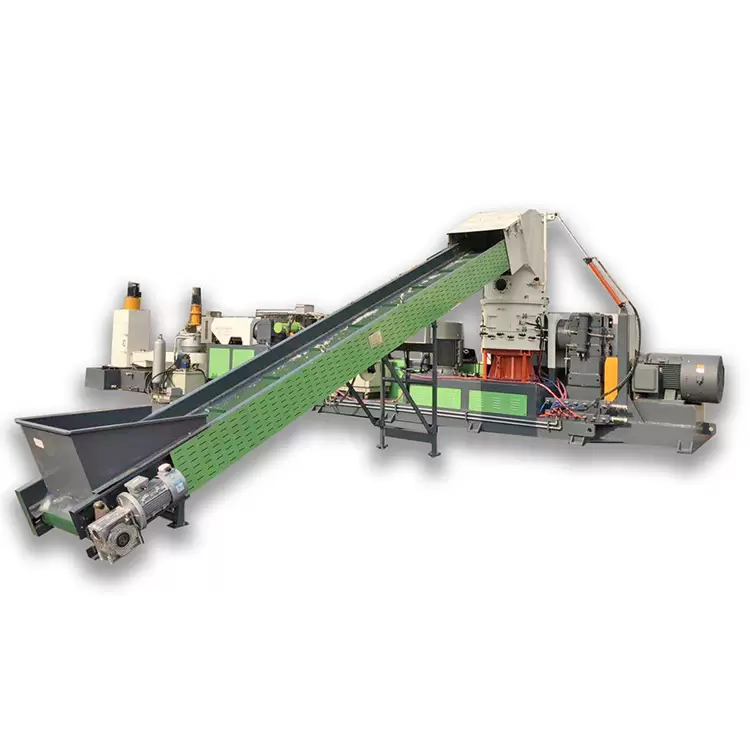

Due to the difficulty in granulation, feeding, bridging, and low production capacity of PE and PP films, advanced foreign technology has been introduced and a forced feeding structure has been adopted, which has a certain crushing function. After pre plasticizing the film, the material is forced into the screw extruder, thereby increasing production capacity; By using the exhaust function, the particles produced are plump and have good glossiness. The production capacity can range from 200 to 1500kg/hr, which is comparable to similar equipment abroad.

Plastic film granulation production line mainly for various types of agricultural films, packaging films, life preservation films, as well as low-density LDPE, high-density HDPE, PET films, and other recycled plastics for granulation

What benefits can purchasing our products

bring to you

We have 9000 square meters workshop. With more than 50 workers. and has dozens of processing equipment, including milling machines, lathes, grinders, drilling machines, etc.

Our company provides one-stop services from processing design, processing to finished products, with a high degree of process automation and short processing cycles, effectively controlling costs.

In processing, we focus on communication, understand customer needs, and enable customers to enjoy the highest quality processing services.

Our company has a spacious workshop, high-end equipment, and high-quality processing services, making it a worthwhile partner for cooperation

The washing line can remove most impurities from the products.

Such as PET washing line. Our machine can remove metals. glue. papers. dirty. oil and some other impurities from PET flakes. Final PET flakes can work with PET strap line. Fiber line. PET sheet line and so on. And for PP/PE flakes and film washing line. Our machine can work for agriculture films. dirty flakes. Jerican. shopping bags and other materials. Remove dirty waste from materials. Make dirty to clean materials. To get re-use. and get profit for our customer.

Professional plastic recycling equipment solution provider to provide

you with one-stop product solutions