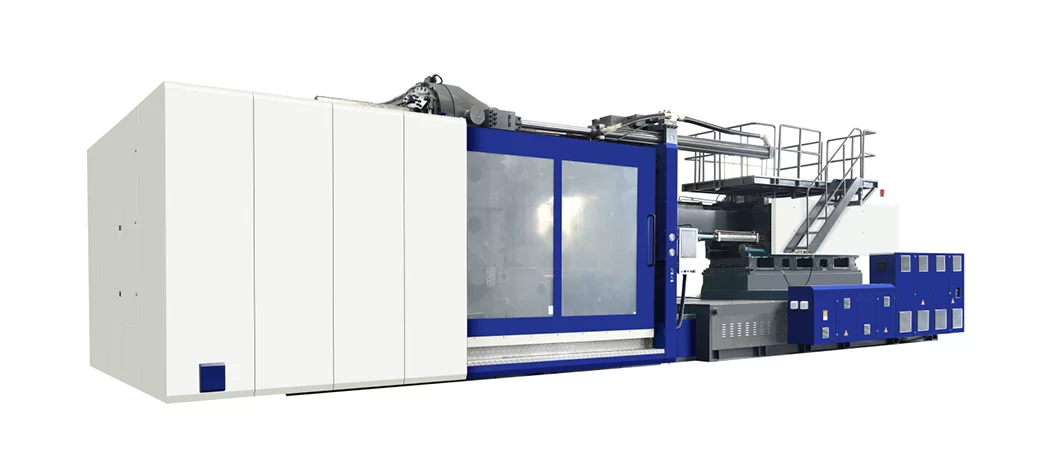

Plastic injection molding machine is abbreviated as injection molding machine, Screw injection molding machines with a capacity of over 2000 tons mainly include injection devices, mold clamping devices, hydraulic transmission systems, and electrical control systems.

Injection device, mainly composed of screw, barrel, nozzle, hopper, measuring device, transmission device

Composed of injection seat and mobile hydraulic cylinder.

The mold closing device mainly consists of front/rear fixed templates, moving templates, Golin columns (commonly known as pull rods), mold closing hydraulic cylinders, mold moving hydraulic cylinders, mold locking mechanisms, mold adjustment devices, product ejection devices (commonly known as neutron), etc.

Hydraulic transmission system and electrical control system. The biggest difference between the second board injection molding machine and the third board injection molding machine lies in the clamping device part. The clamping device of the second board injection molding machine mainly includes a moving template, a static template, a rotating nut system, a hydraulic ejector pin system, a rapid mold moving system, and a high-pressure hydraulic cylinder locking system. The locking force is provided by the high-pressure hydraulic cylinder.

2 platen plastic injection molding machine mainly operates in a direct compression mode, which involves four high-pressure locking hydraulic cylinders simultaneously pulling the Goering column to pressurize and maintain the mold. The main process of producing plastic parts in the second board injection molding machine is: slow mold closing - fast mold closing - low pressure slow mold closing - rotating nut locking - high-pressure locking hydraulic cylinder locking - injection - pressure maintaining - pressure releasing after pressure maintaining - high-pressure mold opening - nut opening - slow mold opening - high-speed mold opening - slow mold opening - product ejection - ejector pin return. The locking process is relatively simple. After the mold is closed in place, the nut rotates and the high-pressure locking hydraulic cylinder provides

Locking force. The mold opening process is the opposite of the mold locking process. Firstly, the high-pressure mold locking hydraulic cylinder is depressurized, then the nut is rotated to open, and then the mold is moved back.

Advantage.

The hydraulic cylinder for mold opening requires less mold opening force. Generally, hydraulic cylinders for injection molding machines with a capacity of over 2000 tons require a molding force of less than 110 tons, which is half of the molding force for three plate injection molding machines of the same tonnage. Hydraulic cylinders with low mold opening force are easy to machine, easy to maintain during actual use, have a longer service life, and are not easily damaged.

The locking force can be freely set. The second board injection molding machine can change the clamping force by changing the number of hydraulic cylinders and the working force of the hydraulic cylinders.

The locking accuracy is relatively high. The error between the set locking force of the second board injection molding machine and the actual locking force generated is small, and the actual locking force can be measured by measuring the oil pressure of the hydraulic cylinder through a sensor embedded in the hydraulic cylinder.

The second board injection molding machine adopts a direct compression locking mold, and the parallelism of the dynamic and static templates is easy to adjust. Generally, it takes a short time to adjust to the parallelism required by the process.

| ITEM | SPECIFICATION | UNIT | PKI620U | PKI650U | PKI750U | PKI900U | PKI1050U | PKI1200U | PKI1400U | PKI1600U | PKI1800U | PKI2000U | PKI2400U | PKI2800U | PKI3300U | PKI4000U | ||||||||||||||||||||||||||||

| INJECTION UNIT | Screw Diameter | mm | 85 | 90 | 95 | 85 | 90 | 95 | 95 | 100 | 105 | 100 | 105 | 115 | 100 | 110 | 120 | 110 | 120 | 130 | 120 | 130 | 140 | 130 | 140 | 150 | 130 | 140 | 150 | 140 | 150 | 160 | 160 | 170 | 180 | 190 | 200 | 210 | 200 | 210 | 220 | 240 | 260 | Special |

| Screw L/D Ratio | L/d | 22.3 | 19.7 | 18.6 | 22.3 | 19.7 | 18.6 | 21.2 | 20.1 | 19.1 | 23 | 21.9 | 20 | 24.2 | 22 | 20.2 | 24 | 22 | 20.3 | 24 | 22.2 | 20.6 | 22 | 20.4 | 19 | 22 | 20.4 | 19 | 24 | 22.4 | 21 | 22.3 | 21 | 19.8 | 23.2 | 22 | 21 | 22 | 21 | 20 | 22 | 22 | Special | |

| Shot size | cm3 | 2327 | 2609 | 2907 | 2327 | 2609 | 2907 | 2977 | 3300 | 3636 | 4082 | 4500 | 5398 | 4006 | 4847 | 5768 | 5224 | 6600 | 7746 | 7307 | 8575 | 9945 | 8369 | 9590 | 11009 | 8369 | 9590 | 11009 | 10462 | 12010 | 13665 | 19463 | 21972 | 24633 | 31756 | 35186 | 38793 | 36914 | 40698 | 44666 | 56549 | 79640 | Special | |

| Injetion Weight(PS) | g | 2118 | 2374 | 2645 | 2118 | 2374 | 2645 | 2709 | 3003 | 3309 | 3715 | 4095 | 4912 | 3645 | 4410 | 5249 | 5046 | 6006 | 7049 | 6605 | 7804 | 9050 | 7524 | 8727 | 10018 | 7524 | 8727 | 10018 | 9520 | 10929 | 12435 | 17712 | 19995 | 22417 | 28898 | 32020 | 35302 | 35592 | 37036 | 40647 | 51459 | 72473 | Special | |

| Injetion Rate | g/s | 543 | 608 | 678 | 543 | 608 | 678 | 562 | 623 | 686 | 629 | 694 | 832 | 672 | 813 | 968 | 813 | 968 | 1136 | 1061 | 1245 | 1443 | 1208 | 1401 | 1609 | 1293 | 1499 | 1721 | 1401 | 1609 | 1830 | 1354 | 1529 | 1714 | 1781 | 1973 | 2175 | 1830 | 2018 | 2214 | 2718 | 3141 | Special | |

| Plasticizing Capacity | g/s | 63 | 74 | 88 | 63 | 74 | 88 | 72 | 85 | 95 | 85 | 94 | 113 | 101 | 121 | 140 | 121 | 140 | 161 | 138 | 159 | 182 | 139 | 151 | 165 | 139 | 151 | 165 | 132 | 162 | 196 | 160 | 192 | 228 | 182 | 212 | 243 | 212 | 243 | 265 | 285 | 297 | Special | |

| Injection Pressure | Mpa | 163 | 146 | 131 | 163 | 146 | 131 | 158 | 143 | 130 | 201 | 182 | 152 | 211 | 174 | 146 | 205 | 172 | 147 | 172 | 147 | 127 | 163 | 142 | 123 | 163 | 142 | 123 | 168 | 146 | 129 | 184 | 163 | 146 | 152 | 137 | 125 | 210 | 142 | 129 | 152 | 127 | Special | |

| Screw speed | rpm | 0-150 | 0-150 | 0-150 | 0-150 | 0-130 | 0-110 | 0-120 | 0-110 | 0-105 | 0-100 | 0-100 | 0-85 | 0-60 | 0-50 | 0-50 | 0-40 | 0-40 | Special | |||||||||||||||||||||||||

| CLAMPING UNIT | Clamp Tonnage | Kn | 6200 | 6500 | 7500 | 9000 | 10500 | 12000 | 14000 | 16000 | 18000 | 20000 | 24000 | 28000 | 33000 | 40000 | ||||||||||||||||||||||||||||

| Space Bet. Tie-bars | mm | 910×820 | 960×900 | 1070×940 | 1100*970 | 1200x1050 | 1300x1100 | 1400x1280 | 1500x1360 | 1580x1480 | 1650x1550 | 1840x1640 | 1900x1700 | 2200x1900 | 2400x2000 | |||||||||||||||||||||||||||||

| Toggle stroke | mm | 1500/900 | 1800/1200 | 1700/1000 | 1900/1250 | 2050/1350 | 1900/1200 | 2450/1400 | 2600/1600 | 2900/1800 | 2850/1750 | 2950/1850 | 3300/2150 | 3200/2100 | 3500/2300 | |||||||||||||||||||||||||||||

| Max.Mold height | mm | 1000 | 1000 | 1100 | 1100 | 1200 | 1300 | 1500 | 1700 | 1800 | 1850 | 1900 | 2000 | 2100 | 2200 | |||||||||||||||||||||||||||||

| Min.Mold height | mm | 400 | 400 | 400 | 450 | 500 | 600 | 650 | 700 | 700 | 750 | 800 | 850 | 1000 | 1000 | |||||||||||||||||||||||||||||

| Max.daylight | mm | 1900 | 2200 | 2100 | 2350 | 2550 | 2500 | 3100 | 3300 | 3600 | 3600 | 3750 | 4150 | 4200 | 4500 | |||||||||||||||||||||||||||||

| Ejector stroke | mm | 300 | 300 | 300 | 330 | 350 | 350 | 350 | 400 | 400 | 450 | 450 | 450 | 500 | 550 | |||||||||||||||||||||||||||||

| Ejector tonnage | Kn | 150 | 150 | 150 | 210 | 280 | 280 | 280 | 360 | 360 | 400 | 400 | 400 | 500 | 550 | |||||||||||||||||||||||||||||

| Ejector number | pc | 17 | 17 | 17 | 17 | 17 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 33 | 33 | |||||||||||||||||||||||||||||

| GENERAL | Max.pump pressure | Mpa | 17.5/21 | 17.5/21 | 17.5/21 | 17.5/21 | 17.5/21 | 17.5/21 | 17.5/21 | 17.5/21 | 17.5/21 | 17.5/21 | 17.5/21 | 17.5/21 | 17.5/21 | wai | ||||||||||||||||||||||||||||

| Pump motor power | Kw | 31+42+13 | 31+42+13 | 48+48+13 | 60+48+13 | 60+60+13 | 48+48+48+13 | 60+48+48+13 | 60+60+48+13 | 60+60+60+13 | 60+60+60+19+21 | 60+60+60+27+21 | 60+60+60+42+21 | 60+60+60+60+21 | 60+60+60+60+60+60+21 | |||||||||||||||||||||||||||||

| Heater Power | Kw | 34.8 | 34.8 | 46.45 | 58.45 | 68.45 | 74.35 | 84 | 95.05 | 95.05 | 110.7 | 140 | 187.6 | 187.6 | 310 | |||||||||||||||||||||||||||||

| Machine Dimenshion | m | 7.9×2.7×2.5 | 8.6×2.6×2.5 | 8.5×2.7×2.5 | 9.3*3.2*2.7 | 9.6×3.4×3.2 | 11.5×3.7×3.6 | 12.9×3.8×3.8 | 13.0×4.0×4.0 | 13.4×4.1×4.2 | 13.6×4.3×5.0 | 15.2×4.5×5.2 | 16.6×4.9×5.3 | 19.3×4.9×5.5 | 20.1×5.4×6.0 | |||||||||||||||||||||||||||||

| Machine weight | T | 25 | 25 | 30 | 40 | 46 | 58 | 70 | 83 | 100 | 112 | 148 | 186 | 198 | 256 | |||||||||||||||||||||||||||||

| Oil tank Cap. | L | 950 | 950 | 1000 | 1100 | 1250 | 1500 | 1700 | 2200 | 2200 | 2400 | 3200 | 3500 | 3900 | 4500 | |||||||||||||||||||||||||||||